Posted at 13:58h

in

3D Printing

Fast, and unsurpassed for high resolution detail, accuracy, and surface finish, SLA and DLP based resin printing is proven technology that has taken a solid foothold in the prosumer 3D printing market. There are fewer entries here than the overladen FFF/FDM field for several reasons, but it can still be difficult to separate the wheat from the chaff.

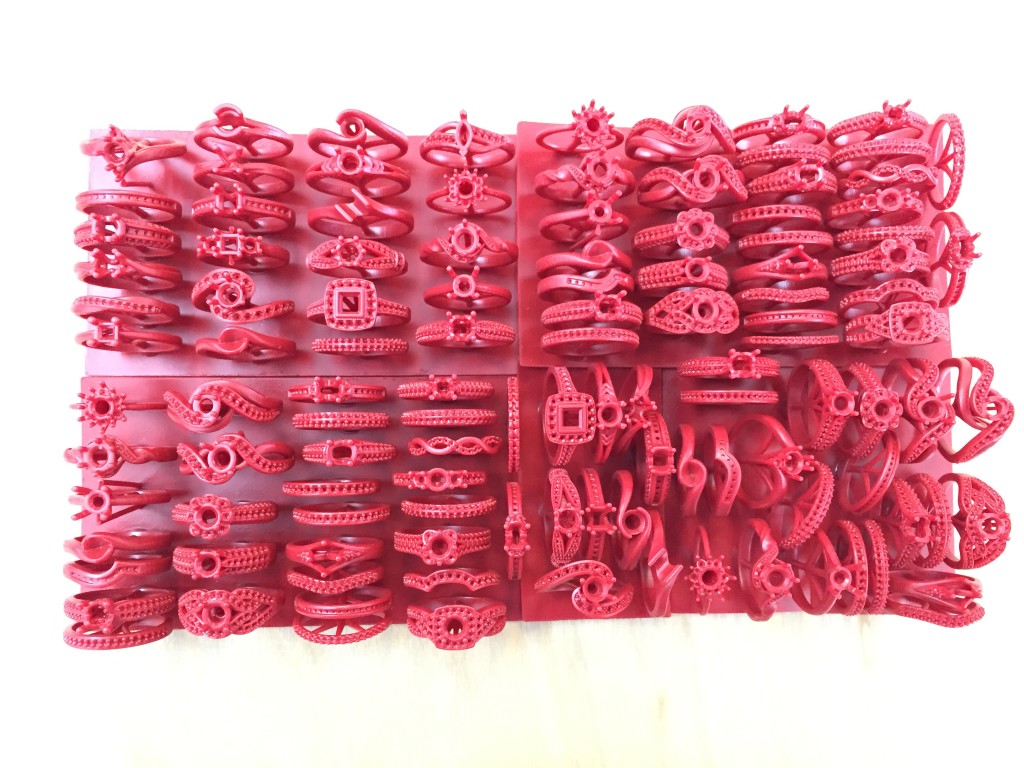

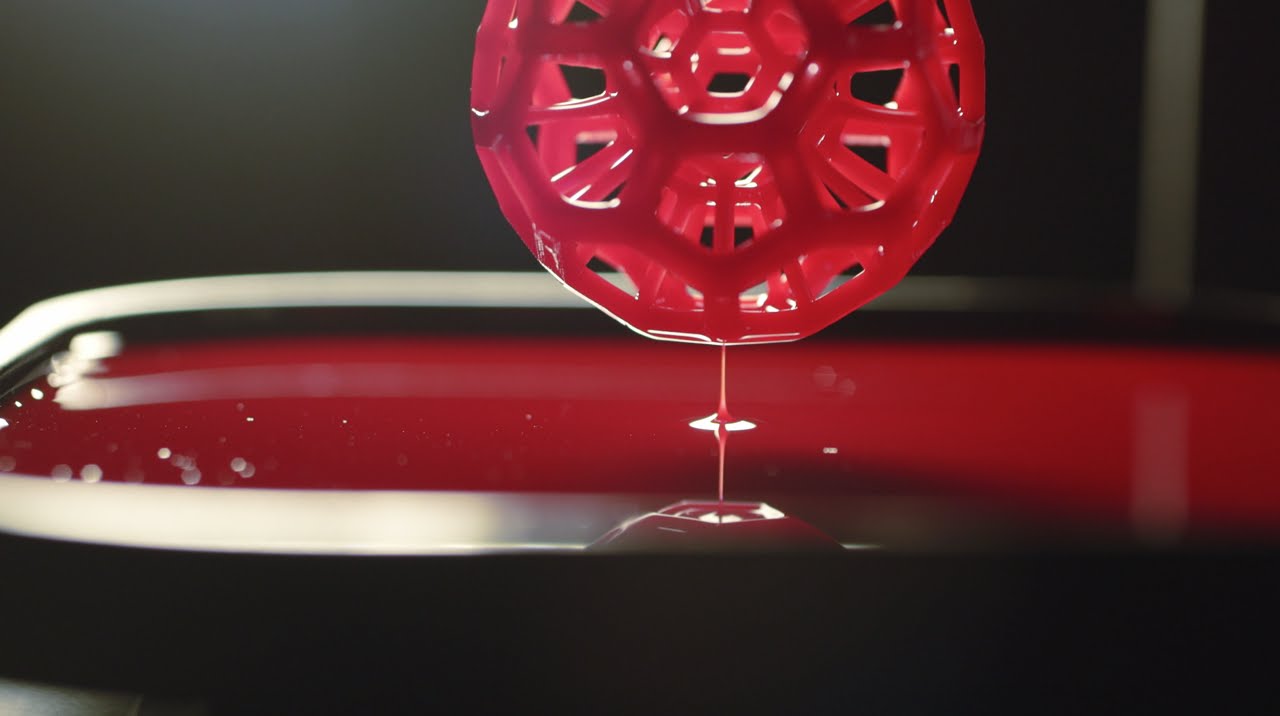

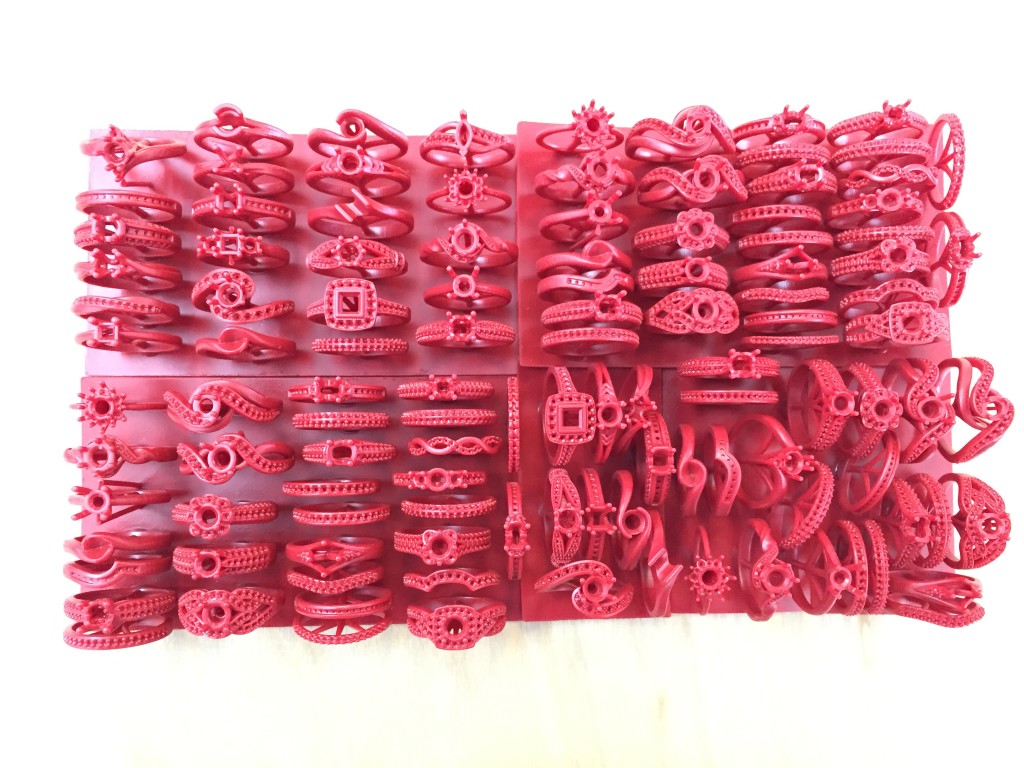

I've been considering the upgrade to resin printing for several years because of its particular suitability to jewelry production. Build volumes can be somewhat limited because of focusing limitations with the relative resin-curing light sources (laser for SLA and digital image projector for DLP), but that doesn't affect most jewelry applications. Castable resins are available to allow printing "wax" for lost wax casting. DLP allows curing an entire layer at once, relative to the slower process of tracing a line with a laser, so it lends itself to printing trays full of densely packed small parts.

[caption id="attachment_2625" align="aligncenter" width="1280"]

By Fernando Cortez, via B9Creator[/caption]

Promises abound in the 3D printing world, but delivery is another thing. With extrusion based FFF/FDM printing, the market has years of industrial and open source development to build upon. Resin printing has only more recently broken loose into the wild. There are open source projects you can follow here, but there are fewer examples, and a smaller community. There are also larger problems to solve and the whole thing costs more than building your own filament printer. For this reason, I would highly recommend choosing an established and proven performer, like one of the following printers.

Solutions are either mechanical or material.

Solutions are either mechanical or material.

By Fernando Cortez, via B9Creator[/caption]

Promises abound in the 3D printing world, but delivery is another thing. With extrusion based FFF/FDM printing, the market has years of industrial and open source development to build upon. Resin printing has only more recently broken loose into the wild. There are open source projects you can follow here, but there are fewer examples, and a smaller community. There are also larger problems to solve and the whole thing costs more than building your own filament printer. For this reason, I would highly recommend choosing an established and proven performer, like one of the following printers.

By Fernando Cortez, via B9Creator[/caption]

Promises abound in the 3D printing world, but delivery is another thing. With extrusion based FFF/FDM printing, the market has years of industrial and open source development to build upon. Resin printing has only more recently broken loose into the wild. There are open source projects you can follow here, but there are fewer examples, and a smaller community. There are also larger problems to solve and the whole thing costs more than building your own filament printer. For this reason, I would highly recommend choosing an established and proven performer, like one of the following printers.